Description

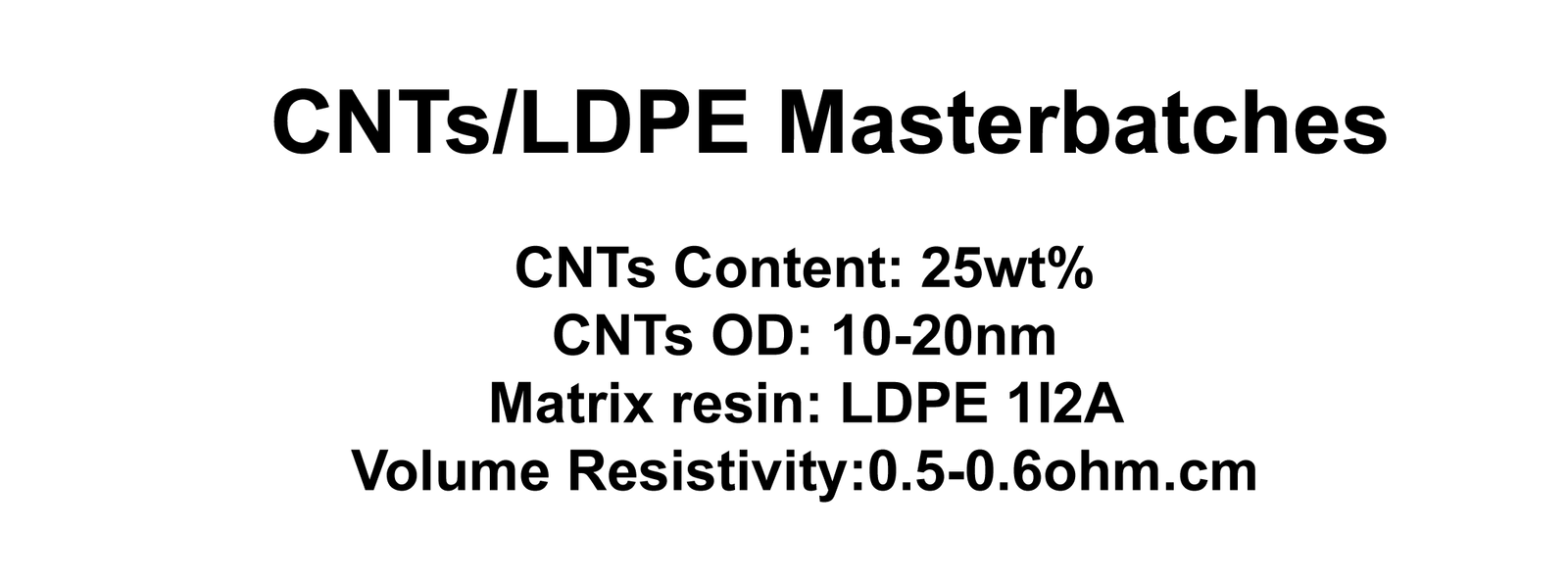

Product Code: CNB-8-TNLDPE

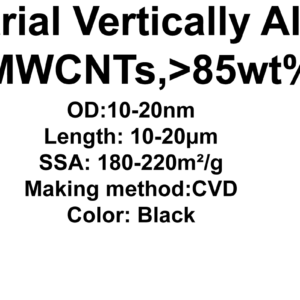

Specification:

[1] The code of matrix resin can be changed according to the customer’s demand.

[2] Typical values refer to the average laboratory data, which is used only for reference when used, not as the standard of the product.

[3] The test sample was a round sheet, which was prepared by hot compression moulding with a thickness of 1.4mm.

[4] The content of CNTs in the masterbatch was diluted to 3% by matrix resin through twin screw extruder. Then the round sheet was prepared by hot compression moulding with a thickness of 1.4mm. And it is tested by a hand-held surface resistance meter.

The specimens were made by compression moulding, and its thickness is 1.4mm. The resistivity were measured by four probe method.

- Decreased risk of chemical contamination

- Excellent electrical conductivity

- Lower application amount than carbon black

- Good for flame retardancy.

| Proportion | Burning Phenomena | Time | UL94 | |

|---|---|---|---|---|

| A | PP 68% FR 32% | 1st:flame, non-drops | t1<10s | V-2 |

| 2nd:flame, drops | t2<10s | |||

| B | PP 48% FR 32wt% CB 10wt% | 1st:non-flame, non-drops | t1>30s | NG |

| 2nd:non-flame,non-drops | t2>30s | |||

| C | PP 48% FR 32wt% CNTs 10wt% | 1st:non-flame, non-drops | t1<1s | V-0 |

| 2nd:non-flame,non-drops | t2<10s |

FR: Fire retardant(24%DBDPO+8%Sb2O3)

CB: Carbon black

Announcements

1.This masterbatches are stored in the same way as ordinary modified polyethylene without drying before used.

2.If you produce some kind of special antistatic material by diluting this masterbatch, it is recommended to use double screw extruder, and choose screw combination with strong shear force as far as possible.

3. CNTs have a significant viscosity-increasing effect on the polymer. The more CNTs are added, the more significant the effect is.

4. Different polymers have different percolation threshold.

5.When the type and content of CNTs are constant, for the same kind of polymer, the higher the melting index, the easier the CNTs are dispersed and the lower the electrical resistivity.

6.Different molding methods have a very prominent impact on the electrical conductivity of the product.

7. If the material remains unchanged, the product’s resistivity is like this: injection molded > the extruded > the hot compression molded.

8.The process conditions also have influence on the product’s resistivity. For example, during injection molding, high mold temperature or high pressure and low speed can make the product’s resistivity lower.

9.The customer needs to obtain the best molding process through experiments.

10.The resistivity measured by different test methods or standards is usually inconsistent and cannot be

directly compared with each other.

Reviews

There are no reviews yet.